Zeller+Gmelin’s series of premium dry offset printing inks were developed for the high-speed, high volume dairy and food container market. Inks expertly formulated to satisfy the high demands associated with today’s food packaging printers. Maximize your efficiency with higher press speeds, reduce set-up waste costs and provide end-use products that speak quality with Zeller+Gmelin UV-curable dry offset printing inks.

In accordance with current FDA regulations, 77/78 SERIES inks are fully capable of meeting all applicable safety requirements for incidental food contact applications.

EarthPrint™ combines the enhanced chemical, water and scratch resistance properties of the 71 series LED inks, with full wash off capabilities. Formulated to combat raw material shortage, EarthPrint™ is highly recyclable, allowing cleaner recycled materials to use in manufacturing. Achieve your performance goals with Zeller+Gmelin dry offset printing inks – contact a Zeller+Gmelin team member today to get started.

> Download Product Brochures below <

Zeller+Gmelin Dry Offset Inks are best used for:

Food Containers

DAIRY & FOOD CONTAINERS, TUBES, JARS & CAPS

Utility Containers

UTILITY PAILS, BUCKETS, & TUBES

And are well known for the following attributes:

UV & LED Curable Formulas

High Adhesion/ Low Migration

High Color Strength & High Gloss

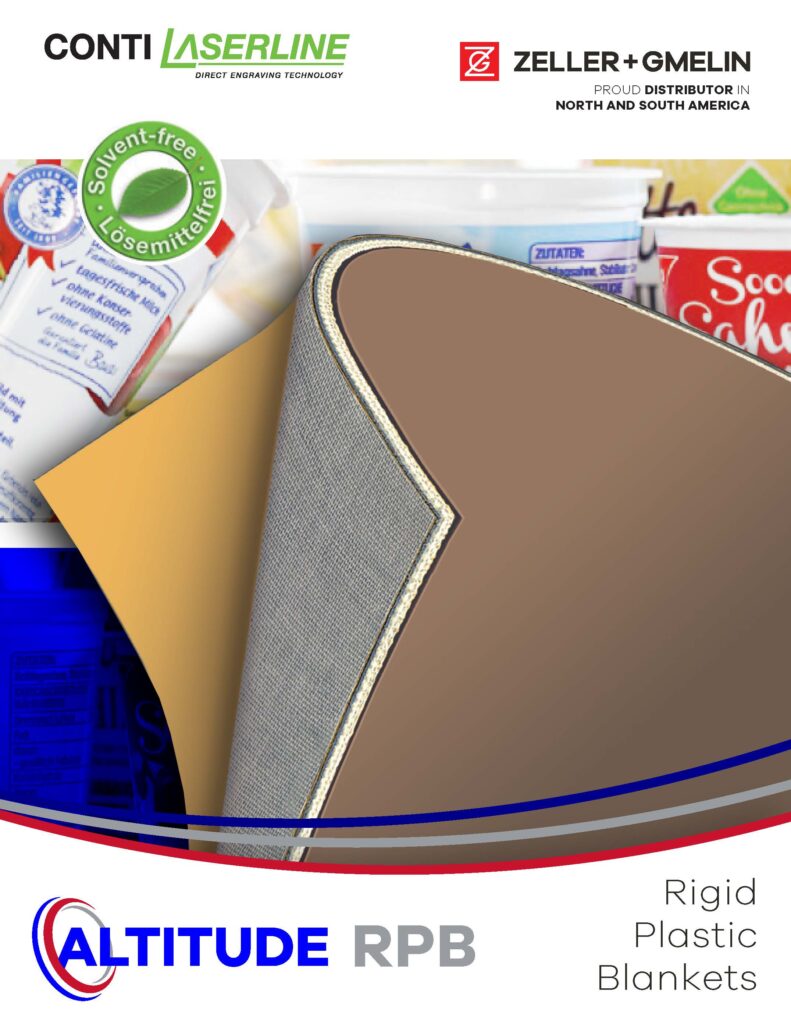

Altitude Rigid Plastic Blankets

Now sold by Zeller+Gmelin

A versatile self-adhesive printing form for printing of cylindrical and conical plastic containers. Used with UV and LED curing ink systems.

ᆞRoll material or self-adhesive formats

ᆞNo swelling / stable in all dimensions

ᆞMinimal thickness tolerances

ᆞLess abrasion

ᆞLong service life

ᆞAbility to print multiple jobs