Understanding Lightfastness in Printing Inks

Lightfastness is the ability of printing inks to resist fading or discoloration when exposed to artificial or natural light. It is a critical characteristic, particularly in applications where the final product will likely be displayed, stored, or used in well-lit environments, such as retail shelves or outdoor settings. Lightfast inks are responsible for maintaining print integrity, quality, ink permanency, and even product freshness, in the face of constant sun and/or artificial light.

Zeller+Gmelin is a proud manufacturer of a variety of lightfast inks for sheetfed offset, web offset, dry offset and flexo printing applications. To achieve acceptable lightfastness, Zeller+Gmelin uses high-quality pigments, dyes, and formulations resistant to UV radiation and other light sources. Verified through extensive testing, Z+G lightfast inks are proven to withstand the degrading effects of light exposure and retain their original colors and appearance over an extended period.

Advantages of Lightfastness

In printing, lightfastness is a key consideration for ensuring that the printed graphics maintain their vibrancy and clarity over time. Products and posters exposed to sunlight or artificial light sources for prolonged periods can experience color fading or changes, leading to a loss of visual appeal and potential damage to a brand’s image. There are many advantages to using lightfast inks:

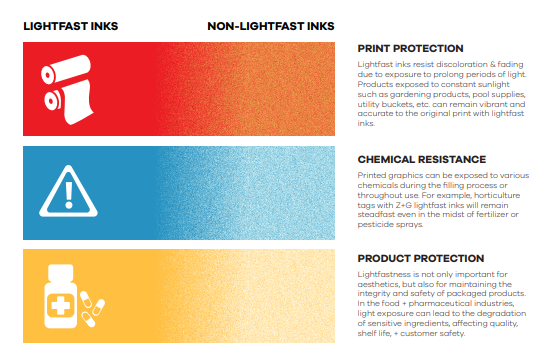

Print Protection. Lightfast inks resist discoloration and fading due to exposure to prolonged periods of light. This ink characteristic is an important factor in maintaining the brand image through various environments and uses. Lightfast inks maintain print permanency and brilliance throughout the product lifecycle. Products exposed to constant sunlight such as horticulture tags, garden and pool supplies, utility buckets, and outdoor signage can remain vibrant and accurate to the original print, when using lightfast inks.

Chemical Resistance. Lightfast pigments are known for their resistance to various forms of light, but they can also be formulated to withstand exposure to various chemicals during the filling process or throughout product use. For example, lightfast horticulture tags may come into contact with fertilizer, sprays or water, which require special ink formulation to avoid damage from chemicals or moisture.

Compliance & Permanency. Some areas of packaging are extremely important to maintain throughout product use in order to protect the safety of consumers. Product descriptions, instructions, warning labels and compliance information are crucial to proper product use and consumer safety. These print sections musts be maintained throughout the entire product life cycle. Lightfast inks can be used to ensure the permanency of these important safety features of your packaging.

Recyclable Packaging. If your containers and packaging are designed to be recycled, lightfast inks are a good option due to their ability to adhere effectively to the print material and not bleed into the wash cycle during recycling. If the pigments were to degrade in the wash, it could detrimentally color the plastics to be recycled and reduce the material’s recyclability.

By using inks with excellent lightfast properties and selecting appropriate materials, printers and manufacturers can ensure that their products maintain their visual appeal, brand integrity, and product quality throughout their intended lifespan, along with the consumer safety and environmentally friendly benefits.

Measuring Lightfastness

When developing fade-resistant inks, our pigments are chosen to meet minimum Blue Wool Scale standards (ISO 105 B02) of 5 through 8 when lightfastness is required in the final product application. To determine lightfastness of printed products, Zeller+Gmelin conducts various tests under controlled conditions, simulating real-world exposure to natural outdoor light and weathering conditions using a Xenon Arc fadeometer. By conducting controlled exposure tests and using color measurement techniques, the lightfastness of printing inks can be accurately evaluated and chosen to ensure the longevity and visual quality of your final printed product.

It’s important to consider that the measure of light degradation depends on several variables. For example, print exposed during July may last 20 – 25 days, while the same print exposed in November could theoretically last up to 140 days.

Additionally, you may want to subtract additional days for differences in latitude, altitude, location, exposure to air pollution and other chemicals, humidity, and weathering effects. The bottom line is that, while the Blue Wool Scale is useful in choosing the correct pigmentation for your product, the customer must ultimately monitor and test their own results under their unique application and field conditions.

Important Considerations for Lightfast Printing Inks

There are several important factors to consider when deciding on lightfast inks and which Blue Wool Scale rating is needed for your application. Here are some print best practices and “need-to-know” information from the ink specialists at Zeller+Gmelin:

Lightfast inks are available in a limited number of pigments and are not available for bright fluorescent or pastel colors. These inks tend to use darker and “dirtier” pigments to withstand the elements and light exposure for long periods of time so it is important to ensure the print design can be achieved with these specialized pigments.

Not all coatings are compatible with lightfast inks and can reduce the effectiveness of their fade resistance properties. Check with Zeller+Gmelin to ensure your coating effectively maintains lightfastness in the various field environments required.

If your product is intended to be used for an extended period, it is best to use lightfast inks to maintain the packaging print throughout its full product use – or at least in the instruction and compliance sections. This can ensure your brand colors stay true and important information does not fade over time.

Lightfast and “weatherable” are two different characteristics of inks. If your product is used and stored outdoors, the ink must be both lightfast and weatherable. Whereas, if your product is solely used indoors, then lightfast ink will suffice. Weatherable inks are always lightfast, though lightfast inks are not always weatherable.

Remember that the lightfastness of the pigments will vary relative to your final product application and exposure. Be sure to test the print under your unique conditions to ensure it will withstand the degrading elements found in your desired environment.

Zeller+Gmelin Ink Specialists are knowledgeable in lightfast and weatherable inks and can assist you in choosing the best color solution for your print application. Contact our team to learn more about this important ink characteristic and discover the best rating recommended to achieve your print and brand goals.

Advantages of Lightfast Inks

Lightfastness is the ability of printing inks to resist fading or discoloration when exposed to artificial or natural light. It is a critical characteristic, particularly in applications where the final product will likely be displayed, stored or used in well-lit environments, such as retail shelves or outdoor settings. READ MORE