De-Ink Rigid Plastics with EarthPrint Eco-Friendly Inks

Years ago, ink manufacturers were tasked with the challenge of formulating robust inks for rigid plastics that adhere incredibly and never wash off. Now, ink producers are being challenged with the exact opposite! With sustainability demands and supply chain instability amplifying the need for recycled materials, the challenge becomes “how can we effectively de-ink printed plastics so they can be recycled into new containers?”

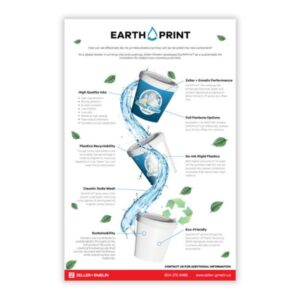

As a global leader in printing inks and coatings, Zeller+Gmelin developed EarthPrint™ as a sustainable ink innovation for today’s eco-conscious printers. In this blog, we’ll discuss the ink and de-ink properties of EarthPrint dry offset inks and the impact they can make in sustainable rigid plastics printing and production.

Ink It Up

EarthPrint eco-friendly dry offset inks were formulated by Z+G for the utmost recyclability, while providing the same high quality color and adhesion properties Z+G inks are known for.

EarthPrint™ inks embody the enhanced chemical, water and scratch resistance properties of Zeller+Gmelin’s 71 series dry offset inks. Though capable of fully de-inking in a caustic soda wash, EarthPrint™ conversely adheres to rigid plastics with great strength and pigmentation. Boasting low odor and low misting properties, these dry offset inks remain stable at high press speeds with free radical chemistry and excellent curing capabilities.

So yes, EarthPrint™ inks are formulated to wash off, but don’t let the de-inking properties fool you. EarthPrint™, like all Zeller+Gmelin inks, are developed for ultimate press performance, pigmentation, adhesion, curing and print quality. Now that we printed our cylinder with the utmost quality, let’s take a look at how to de-ink it down for ultimate recyclability.

De-Ink It Down

As raw material shortages and supply chain volatility continue, accessing virgin plastic material is becoming an expensive feat for many dry offset printers.

Though many rigid plastics are recyclable, the percentage of material eligible for recycling depends on how “clean” you can wash the printed plastic.

With EarthPrint™, the ink formula gives way in the caustic soda wash, removing more pigment and leaving behind brighter, whiter recycled plastics. With higher amounts of ink wash off, the washed materials can be recycled into cleaner containers and tubes that require less virgin material.

Eco-Friendly All Around

Reduce. Re-use. Recycle. Thanks to EarthPrint™ inks, printers can reduce the amount of virgin materials used in recycled plastics, re-use more recycled materials in new products and recycle a higher amount of plastics than ever before.

Printers can contribute to sustainability throughout the full product lifecycle, by creating finished goods that can be recycled with brilliance, while requiring less raw materials.

Rest assured, our R&D Technicians strictly followed all Association of Plastic Recycling (APR) standards and protocols throughout the development and testing of EarthPrint™ to ensure ultimate container recyclability.

If you’re looking for new ways to increase your sustainability efforts in rigid plastics printing, EarthPrint is the solution for a sustainable future. Available in all PANTONE shades, EarthPrint can effectively replace your full dry offset ink inventory. Contact a Zeller+Gmelin Account Manager to discuss your print processes to see if EarthPrint dry offset inks are the best eco-friendly ink for your applications.