Surviving Summer in the Pressroom: How to Protect Ink Adhesion and Label Quality

When implemented effectively, UV LED-curing is proving to be a game-changer for the sheetfed litho industry. As a leading provider of sheetfed offset and web offset energy-curable inks, Zeller+Gmelin is on the forefront of the industry shift to UV LED technologies. Let’s break down the advantages and important factors to consider before making the switch to UV LED.

Flipping the Switch: Advantages of UV LED Offset Printing

When implemented effectively, UV LED-curing is proving to be a game-changer for the sheetfed litho industry. As a leading provider of sheetfed offset and web offset energy-curable inks, Zeller+Gmelin is on the forefront of the industry shift to UV LED technologies. Let’s break down the advantages and important factors to consider before making the switch to UV LED.

Prop 65 Frequently Asked Questions: Essential Insights for Print and Packaging Professionals

Navigating California’s Proposition 65 packaging requirements can feel like a maze for those in the print industry. With over 1,000 chemicals on the list and strict rules around warnings, it’s a lot to unpack. At Zeller+Gmelin, we’re here to simplify it for you.

Key Testing Procedures for UV Shrink Sleeve Printing

UV shrink sleeve printing is a dynamic process requiring meticulous attention to variables like ink selection, substrate treatment, UV curing settings, and film weights. Managing these factors effectively—alongside rigorous quality control testing—ensures consistent, high-quality results for your printed shrink sleeve labels.

Ink Management – Setting up Your Ink Room for Success

Ink management is an important factor for running a seamless and productive printing operation. Without a well-organized system, pressroom managers risk production delays, increased costs, and compromised quality.

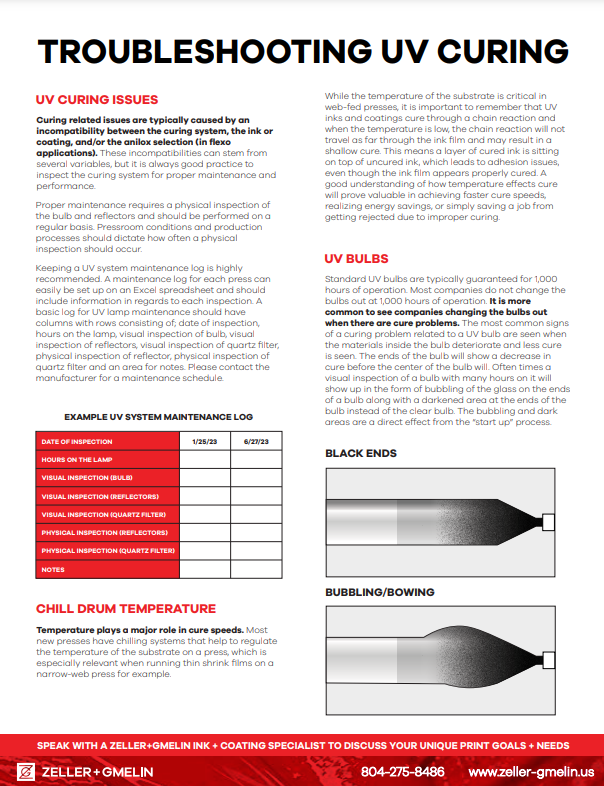

Troubleshooting UV Curing Inks

Check out at this educational white paper reviewing key troubleshooting tips for energy-cure ink systems.

What is Sheetfed Offset Printing?

In a world surrounded by printed materials, from the pages of your favorite magazine to the intricate consumer products packaging, one printing method stands out for its exceptional quality and precision—sheetfed offset printing. What makes sheetfed offset printing even more remarkable is its ability to adapt to a wide range of substrates.

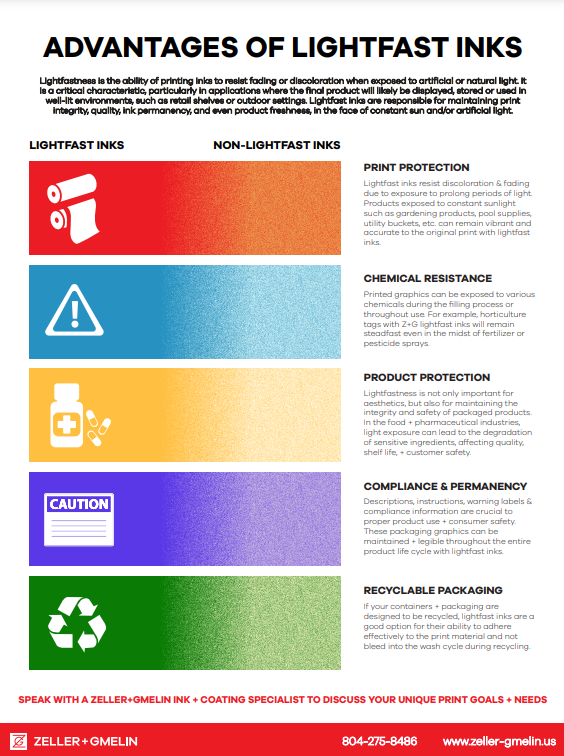

Understanding Lightfastness in Printing Inks

Lightfastness is the ability of printing inks to resist fading or discoloration when exposed to artificial or natural light. It is a critical characteristic, particularly in applications where the final product will likely be displayed, stored, or used in well-lit environments, such as retail shelves or outdoor settings.

Advantages of Lightfast Inks (INFOGRAPHIC)

Check out at this educational infographic outlining the benefits of lightfast ink products from Zeller+Gmelin.

Reduce, Reuse, Recycle: The Journey To Sustainable Plastics Through Ink Innovation

The quest for sustainable plastics stands at the forefront of our environmental challenges. While plastics offer versatility, durability, and convenience in everyday life, their recyclability has become a growing concern for an entire generation. Though we are far from a circular system, the issue of plastic pollution has hastened the drive for innovative, sustainable solutions, especially in the packaging sector.

Understanding Plastic Recycling Symbols (INFOGRAPHIC)

Often found on the bottom of plastic containers, bottles, and packaging, plastic recycling symbols are on nearly every plastic product, but what do they mean? These numbered symbols, also known as resin identification codes, categorize types of plastics for consistent manufacturing and recycling. We’ve created a printable guide to understand what each symbol means, where they’re typically found, and how to best recycle them!

What is Flexographic Printing?

From your morning cup of coffee to the millions of packages delivered daily, flexographic printing has found its place all around us. Flexographic printing is a versatile and widely used production process that caters to many industries. Also known as “flexo printing,” this technique combines letterpress and rotogravure elements to create high-quality prints on a wide variety of substrates.

3 Key Flexo Components for Successful Shrink Sleeve Printing

With years of experience in this sought after application, we have witnessed printers’ success in this application due to the extensive testing and control of three major print categories. In this blog we will discuss the key printing components needed to achieve perfectly shrunk package print. Additionally, we will debunk common myths and share our best practice to help you achieve successful shrink sleeve printing. Enjoy!

Altitude Dry Offset Printing Blankets Perform Like Magic on Rigid Plastics

It’s no illusion, the offset printing blanket is one of the stars of the rigid plastics printing show. However, not every blanket was built for the challenges of dry offset print. There are multiple issues that can arise due to poor printing blankets that can stop the act, causing you to lose in waste and downtime. Are your blankets the source of poor profit margins?

The Competitive Advantages of Z+G Sheetfed Offset Cold Foil Adhesives

As more offset printers take advantage of specialty effects, like cold foil, choosing the right adhesive is imperative to maintaining press performance and print quality. After extensive development and testing in the field for over 2 years, Zeller+Gmelin has released a new cold foil adhesive specifically designed for dual-cure sheetfed offset applications.

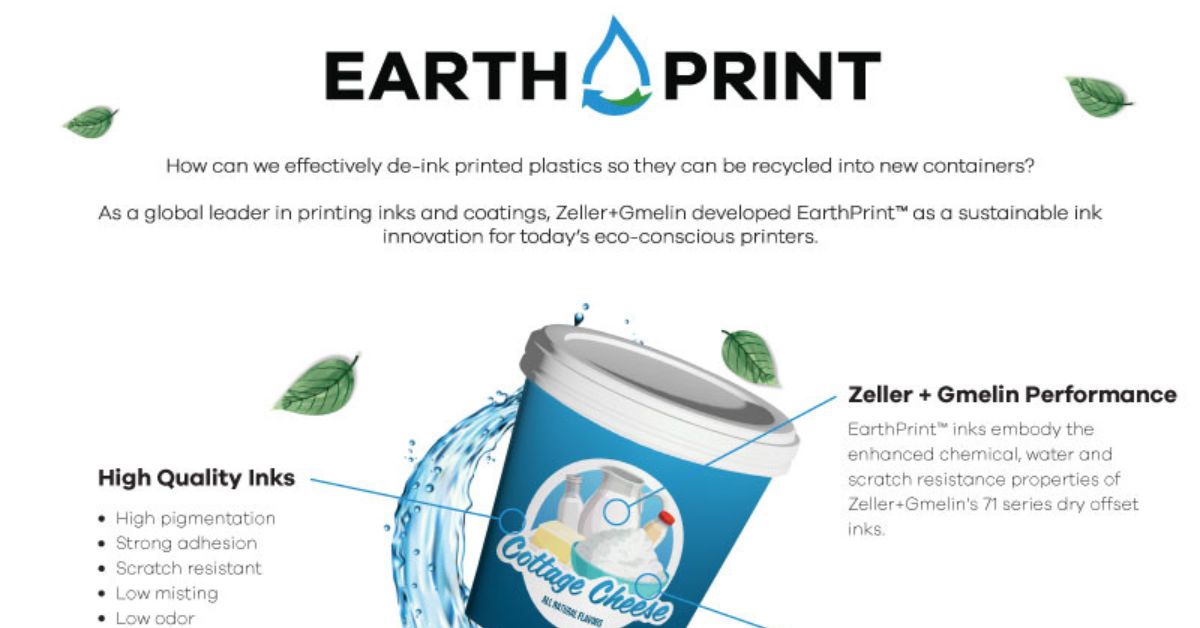

Understanding EarthPrint Dry Offset Inks (INFOGRAPHIC)

Browse through this educational infographic on EarthPrint dry offset inks to discover the features and benefits of the newest ink innovation from Zeller+Gmelin.

De-Ink Rigid Plastics with EarthPrint Eco-Friendly Inks

As a global leader in printing inks and coatings, Zeller+Gmelin developed EarthPrint™ as a sustainable ink innovation for today’s eco-conscious printers. In this blog, we’ll discuss the ink and de-ink properties of EarthPrint dry offset inks and the impact they can make in sustainable rigid plastics printing and production.

6 Tips to Stretch Your UV Coating Supply during an Industry Shortage

At Zeller+Gmelin, we still have many UV coatings, adhesives, varnishes and overprint products in stock and available. However, like everyone in the industry we are also experiencing the brunt of a restricted supply chain. In this blog, we offer tips and tricks for stretching your UV coating supply during this time of limited resources.

Getting Started with LED Flexo Inks: Frequently Asked Questions

At Zeller+Gmelin, we still have many UV coatings, adhesives, varnishes and overprint products in stock and available. However, like everyone in the industry we are also experiencing the brunt of a restricted supply chain. In this blog, we offer tips and tricks for stretching your UV coating supply during this time of limited resources.

The Basics of Flexo Ink Chemistries, Manufacturing & On-Press Maintenance

Ink—that magical, mystical fluid—delights designers, annoys accountants, inspires inkies and P-O’s press operators! We use it in flexo presses every day, all day, across the country and around the world, yet so many people don’t understand how ink really works, what it can and can’t do, and how to use it best to maximize productivity in the pressroom.